- Densification of large areas of loose granular soils and fills for heavy structures.

- Major infrastructure projects such as industrial complexes, heavy warehouses, port facilities, airport runways and aprons, large storage tanks, and large-scale embankments for roads and railways.

- Improvement of uncontrolled fills, demolition debris, and even sanitary landfills to support future construction.

- Mitigation of liquefaction potential in loose, saturated granular soils, especially in earthquake-prone areas.

- Collapsing voids in shallow karst (limestone) geologies to reduce sinkhole potential.

- Treating marginal sites to enable the use of shallow foundations, avoiding the need for deep excavation or piling.

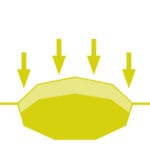

| Dynamic Compaction is known for its ability to improve soils to significant depths, often ranging from 5 to 15 meters (20 to 65 ft), and in ideal conditions, even deeper (up to 30 meters / 100 ft).

The actual depth depends on factors like the weight of the pounder, drop height, number of impacts, grid spacing, and soil characteristics (especially permeability and fines content) | Loose granular soils: Sands, gravels, silts (especially those with low fines content).

Uncontrolled fills: Demolition debris, industrial waste, construction rubble, mixed fills.

Landfills: Old refuse and industrial waste dumps (though treatment is complex and depends on waste composition).

It’s less suitable for highly cohesive (clayey) soils as they tend to absorb the energy and prevent deep penetration, and pore water pressures can build up excessively without proper drainage. If used on cohesive soils (often termed “Dynamic Consolidation”), it requires rest periods for pore water pressure dissipation | - Achieves deep densification in situations where other methods are not feasible or economical.

- Highly effective in increasing the density, stiffness, and bearing capacity of a wide variety of problematic granular soils and fills.

- Reduces post-construction settlement significantly.

- Cost-effective for treating large areas and deep problematic layers compared to deep excavation, removal, and replacement, or deep piling.

- Can often treat a wide range of highly variable, unclassified, or contaminated fills, potentially avoiding their costly removal.

- Relatively simple in concept, making on-site adjustments possible based on observed ground response.

| - Generates very high ground vibrations and noise, which can be a major concern near existing sensitive structures, utilities, or residential areas. Exclusion zones (often 15-30m or more from buildings) are typically required.

- Not suitable for highly cohesive (clay) soils where the energy is absorbed too quickly and water cannot drain effectively.

- Can cause surface loosening during the initial passes before the deeper layers are consolidated.

- The process can be time-consuming due to the grid pattern and multiple passes, and requires precise planning and monitoring.

- Requires a large, open work area with sufficient overhead clearance for the crane and dropping weight.

- Groundwater levels must be carefully managed; it’s generally most effective when the groundwater table is at least a few meters below the surface.

- Requires rigorous quality control through in-situ testing (e.g., CPT, SPT, plate load tests) before, during, and after compaction.

|