What’s the ideal level of compaction for your project?

Soil compaction is a vital stage of any construction project. Compaction determines the stability and longevity of building foundations, as well as roads, airports, railway embankments, bridges, sporting grounds and other infrastructure. Base & sub-base soils needs to be firm enough to carry the load of these built structures and in some circumstances induce settlement while maintaining the capacity for appropriate drainage.

But, it’s not a one-size-fits-all solution. What level of compaction is actually needed for each project? Does it differ depending on the type of build, or the nature of the site, type of soil and soil conditions? And when does over-compaction occur?

Contents:

What factors determine the best compaction approach?

Finding the right compaction level for your project

How to test soil compaction levels

What equipment do you need for ideal compaction?

What factors determine the best compaction approach

All soil compaction calls for a detailed tailored approach to overcome the unique challenges of each site – namely soil conditions, type of compaction, size of site building type, and project timelines.

The first step is to assess soil characteristics in order to determine the optimal compaction level in line with project specs, such as load-bearing requirements, expected traffic, and environmental factors. These aspects will help to determine the ideal moisture content for compaction, typically established through Standard or Modified Proctor tests.

Once you’re across the site specifics, you can choose the correct type of machinery to match the project — whether you need large padfoot rollers for thicker cohesive soil layers across big areas, smooth-drum rollers for granular or mixed materials, or plate compactors for precise work finishing off edges and corners. Assessing / Finding the right equipment ensures that you’re able to overcome any site challenges to finish your build on time and – more importantly – build structures & sites that last.

Finding the right compaction level for your project

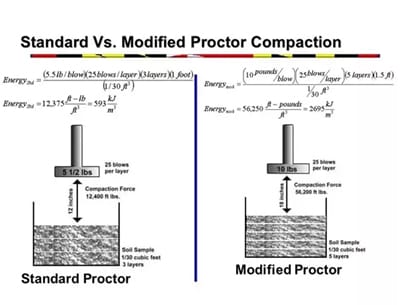

Compaction percentage refers to the density of any given section of base soil. Soil density can be measured using the Proctor compaction test. There are two variations of this procedure – the Standard and Modified Proctor tests (more on that later).

Generally, 95% is considered the benchmark for optimal compaction in construction applications. However, every site requires a tailored approach.

Residential foundations - 95-98%

The right level of compaction for homes and low-rise residential buildings ensures a stable foundation for footings that prevents settling and extends the longevity of the structure.

95-98% on the Standard Proctor test will make the ground stable enough to support the structure without being overly compacted, which could make excavation for utilities more difficult.

Roads and pavements - 98-100%

Road building requires careful consideration of soil compaction to prevent future maintenance issues. Proper compaction provides a stable base for the asphalt or concrete & even dirt Roads, reducing the risk of potholes, rutting, corrugations and cracks.

98-100% is recommended for the base layer, with sub-layers potentially requiring slightly less compaction to ensure suitable drainage.

Commercial building sites - 95-100%

Larger commercial projects demand a higher level of soil stability due to the increased load of the structure. This includes office buildings, retail centres and industrial facilities.

The recommended level is 95-100% for the Modified Proctor test. The Modified Proctor test applies more energy during compaction, simulating the heavier compaction needed for commercial sites.

Landfills - 90-95%

Compaction in landfills is essential for maximising space and managing leachate. The soil used to cover disposed material needs to be compacted to prevent settling and gas escape.

90-95% of compaction allows for effective coverage of waste materials while controlling gas movement and water leaching & will also need to be monitored over time for settlement due to decomposition of material.

Agricultural Land - 85-90%

While excessive compaction can be detrimental to agricultural land, certain land management practices require deliberate compaction to construct waterways, channels & roads.

The recommended level varies depending on the specific circumstances, but it’s generally lower, around 85-90% of Standard Proctor density, to maintain soil health and permeability for water and root growth.

How to test soil compaction levels

Different types of soil require different amounts of moisture to achieve maximum density. This is crucial for the durability of the project and can also be more cost-effective, as it reduces the effort needed to reach the desired level of compaction.

The most reliable way to determine optimum moisture content is via the Standard Proctor Test and Modified Proctor Test.

Standard Proctor Test

The Proctor Test is designed to determine the maximum density that soil can achieve under controlled conditions. This is done by measuring the effect of moisture on soil density and establishing a reference value for the soil’s maximum density, expressed as a percentage.

This reference value is critical for setting compaction targets before the commencement of any project.

Modified Proctor Test

In comparison, the Modified Proctor Test basically incorporates more impact in the testing process. This determines the maximum density of soil needed for more demanding construction projects. It considers higher densities, resulting in higher Modified Proctor values.

Although the methods for both tests are similar, the Modified Proctor Test exerts greater force on more layers of soil to assess the needs of larger projects that require more robust foundations.

The Hand Test

While not a substitute for the more scientific method of the Proctor Tests, the hand test provides immediate insights into the soil’s condition, weather cohesive or non- cohesive generally and helps to understand if further testing or adjustments to the compaction process are required.

To perform this test, a soil sample is squeezed in the palm of the hand. The tester observes the soil’s behaviour upon release. If the soil retains its shape and shows no signs of crumbling this would be deemed as cohesive, it suggests good compaction is possible and the soil has adequate moisture content. If it crumbles easily, the soil may be too dry or not sufficiently compacted & moisture will need to be introduced to site. If water comes out of the soil, it indicates excessive moisture content.

What equipment do you need for ideal compaction?

Reaching the desired level of compaction requires specific tools and techniques.

Moisture testing

Moisture meters help to determine the optimal moisture level for effective compaction, ensuring the soil is neither too wet nor too dry and is usually expressed as a percentage.

These devices work by measuring the amount of water in the soil, either through electrical resistance or capacitance methods, providing a quick and accurate reading of the soil’s moisture content to guide the compaction approach.

Penetrometer

Penetrometers assess soil density by measuring resistance as a rod penetrates the soil, offering a quick and direct method to verify if compaction meets project specs. This tool provides immediate feedback for necessary adjustments, ensuring project stability and durability.

Light compaction equipment

- Tamping rammers. These hand-operated tools are perfect for compacting over pipelines, electrical conduit and smaller areas landscaping such as flower beds, pathways, and around trees, providing a powerful tamping force in confined spaces.

- Plate compactors. For larger landscaping projects like driveways, and walkways, plate compactors are the go-to compaction

Heavy compaction equipment

- Tandem Rollers. These machines are equipped with two large usually Smooth, drums that vibrate or rotate, exerting pressure evenly across surfaces. They’re particularly effective for smaller areas requiring good manoeuvrability, such as driveways & carparks. By applying a consistent compaction force tandem rollers ensure a smooth, durable surface finish, enhancing the driveway’s longevity and appearance.

- Smooth-Drum Rollers. Designed for their exceptional compaction power and efficiency, these rollers are ideal for large-scale applications like extensive residential lots , road construction & maintenance. Smooth-drum rollers work by applying a combination of weight and vibratory forces, making them highly effective in achieving deep compaction for foundations or paving, supporting large structures, and preventing future settlement in large residential areas.

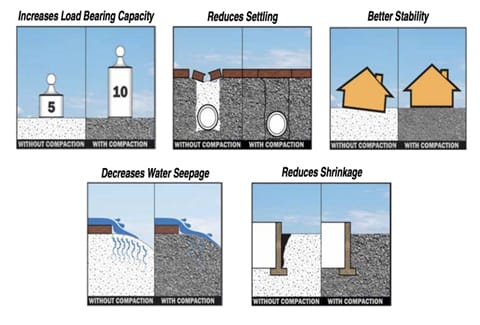

Benefits of proper soil compaction

Achieving the optimal compaction level offers several advantages:

- Enhanced stability. Compacted soil provides a firm foundation for buildings, roads, and other structures, preventing further settling and cracking.

- Improved load-bearing capacity. Compaction strengthens the soil & sub base allowing it to support greater weight without deformation.

- Reduced water flow issues. Proper compaction allows for better drainage, preventing water logging and promoting healthy plant growth in the surrounding area which, in turn, helps to reduce erosion.

- Reduced Settlement Properly compacted soil minimises the risk of the ground settling under the weight of structures, which can lead to uneven foundations, cracking and structural damage over time.

- Reduced shrinkage. Compaction helps to reduce the soil’s potential for shrinkage, which can cause gaps between the soil and foundation structures, leading to instability, cracks in buildings, walls & retaining walls and water intrusion problems.

Need a quick refresher? Check out our simple guide to compaction.

How to avoid over-compaction

While compaction is essential, too much of a good thing can be problematic. Over-compaction is likely to result in:

- Reduced air and water infiltration. In Agricultural & sporting applications this limits oxygen availability for plant roots and restricts water flow, hindering plant growth and healthy soil functions.

- Increased run-off and erosion. Reduced water absorption leads to increased surface run-off, potentially causing soil erosion, rutting & corrugations.

- Soil structure damage. Over-compaction can destroy the aggregate structure of the soil, turning to a powdery formation leading to decreased soil fertility and health.

- Reduced water table recharge. With decreased infiltration, there’s less water percolating through the soil to recharge underground aquifers, potentially affecting local water supplies.

- Equipment stress. Over-compaction often requires more passes, which can increase the wear and tear on your equipment and higher Fuel burn leading to higher maintenance costs and reduced lifespan and increased production costs.

Remember to engage a qualified geotechnical engineer to identify your project’s specific compaction needs. They can assess factors like soil type, intended use, and desired load capacity to recommend the optimal compaction level and suitable equipment.

Combining professional expertise with high-quality compaction equipment is key to achieve the ideal level of compaction for a stable and long-lasting foundation.

Searching for the sweet spot in soil compaction? Get in touch with our team to explore the range of heavy and light compaction equipment for your next project.