Completing projects on time and within budget starts with having the right equipment for the job. When it comes to compacting clay/cohesive soils, padfoot rollers are the ultimate choice of compaction machines. Known for their unique design and versatility, padfoot rollers deliver the precision and durability you need to tackle even the toughest soil conditions for any project.

Machine efficiency has never been more important, making the most of every project’s resources, minimising delays, and avoiding costly reworks. In this guide, we’ll dive into everything you need to know about padfoot rollers – from how they work to why they’re an essential asset on any construction site.

The Fundamentals of Padfoot Rollers

Fine-grained soils like silt and clay might seem to be naturally compact, but hidden air voids can cause serious structural issues if left uncompacted. On large-scale projects, such as highways and building sites, these inconsistencies can lead to costly delays and extensive reworks if the foundation isn’t uniformly compacted from the start.

This is where padfoot rollers excel. Their unique drum design, featuring a series of raised “pads” or “feet” applies a kneading action, along with vibration that breaks up stubborn soil clumps while removing air voids, and filling low-density voids. This process ensures deep, consistent compaction, enabling a stable foundation across a variety of challenging soil conditions.

Key Features of Padfoot Rollers

Unique Drum Design: Protruding ‘feet’ are attached to the drum to work into the soil along with vibration. The result is uniform compaction free from voids and clumps.

Vibrational Functionality: padfoot rollers are equipped with a range of vibration settings designed to work deeper into the soil. You can change the vibration amplitude to either high or low, which also changes the frequency (vibrations per minute) to suit the task.

Levelling Option: Certain padfoot rollers come with an integrated pusher blade that helps level the soil before compaction.

Performance: Benefits of Padfoot Rollers

Working Multiple Soil Types

Cohesive clay and silt-based soils require a more in-depth approach to compaction than is typically possible when using a standard smooth drum, or tandem roller. Because projects run on efficiency, padfoot rollers are designed to compact more granular clay-type soils with only minimal changes to the rollers operating settings.

Elimination of Air Pockets

As every project manager is aware, air pockets/voids, can lead to serious issues on site.

Ergonomic Design

Padfoot rollers are designed for extended initial site use, so significant investment has been made in their ergonomics. Intuitive controls, an expansive field of vision from the cab, and a high degree of operator comfort via noise insulation and vibration elimination in the cab will support operators of all experience levels.

Need a quote for your next hire? Get a Quote.

Padfoot Roller Maintenance Requirements

Padfoot rollers are built with high-grade steel and reinforced drums, ensuring they can withstand the toughest soil conditions without compromising the machines’ integrity or performance. Routine upkeep is streamlined via easy-access maintenance access panels and straightforward onboard checks, allowing operators to perform essential daily and general service inspections quickly.

This combination of robust construction and user-friendly maintenance features ensures easy operation with minimal downtime, keeping projects on track and machinery performing at its best from start to finish. However, maintenance frequency does increase in highly abrasive/harsh operating conditions.

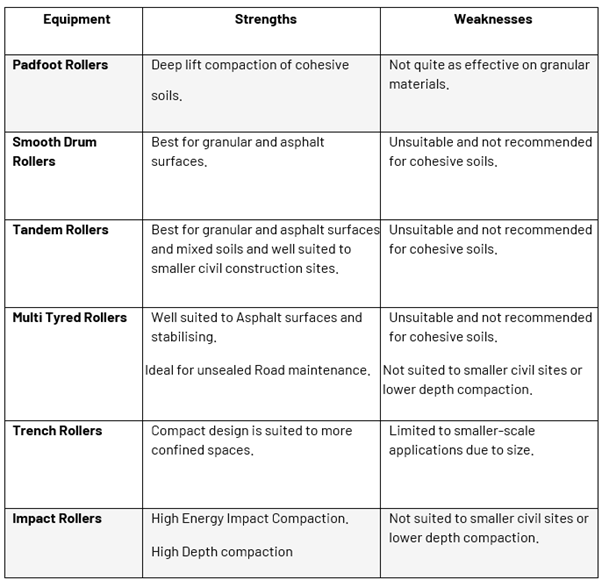

Padfoot Rollers vs Other Equipment

When it comes to soil compaction, choosing the right equipment can make all the difference in achieving a stable and reliable foundation. Different rollers are designed for specific soil types and project requirements, and understanding their strengths and limitations ensures the best performance possible. Below is a concise comparison of padfoot rollers with other compaction equipment:

What Project Managers Say About Padfoot Rollers

At Conplant, we’ve built a reputation for providing reliable, high-performing equipment, and our fleet of padfoot rollers is no exception. Project managers consistently share positive feedback about their experience with our padfoot roller machines and here are some of the most common pieces of feedback we hear when hiring out our fleet:

- High degree of efficiency when compacting clay and silt

- Operator-friendly, comfortable cabin and easy for novice operators to understand control layout quickly.

- Large weight range to suit all site applications.

- Extended use with minimal breakdowns and maintenance

- Surprising levels of operator comfort during long shifts

These insights highlight why padfoot rollers continue to be a go-to choice for demanding projects.

Final Verdict on Padfoot Rollers

When it comes to compacting cohesive soils, padfoot rollers are the clear choice for delivering reliable, uniform results. From foundations and embankments to dams and retaining walls, these machines excel in creating stable bases that will ultimately stand the test of time.

At Conplant, we’re here to ensure you have the right equipment for every stage of your project. Our team of experts is ready to guide you through your options, helping you hire the ideal padfoot roller to meet your needs. Get in touch with us today and keep your project moving forward with confidence.

Frequently Asked Questions

Padfoot rollers compact cohesive soils, so construction projects begin with stable, uniform– solid foundations. They have the ability to fill voids and air pockets in cohesive soils for any size and scope of project.

Most padfoot rollers have a vibration mode and the size and number of the vibrations can be adjusted to suit the exact ground conditions. This is particularly useful for large projects that span several different soil types.

Padfoot rollers are the best tools when working with cohesive soils, while a smooth drum roller is better suited to asphalt or mixed and granular soils.

Compactors certainly have their merits for larger projects, but they will struggle on smaller projects. In these cases, hiring a padfoot roller is the smart move, and it will significantly increase efficiency while reducing any capital outlay and reduce site labour and operating costs.

A padfoot roller is the tool of choice when working with clay, silt, and other cohesive soils that require deep lift compaction. It kneads and vibrates the ground to eliminate air pockets, clumps, and low-density voids – all three of which can cause real issues with the strength and stability of the foundation.