Precision and Efficiency with Völkel Intelligent Compaction

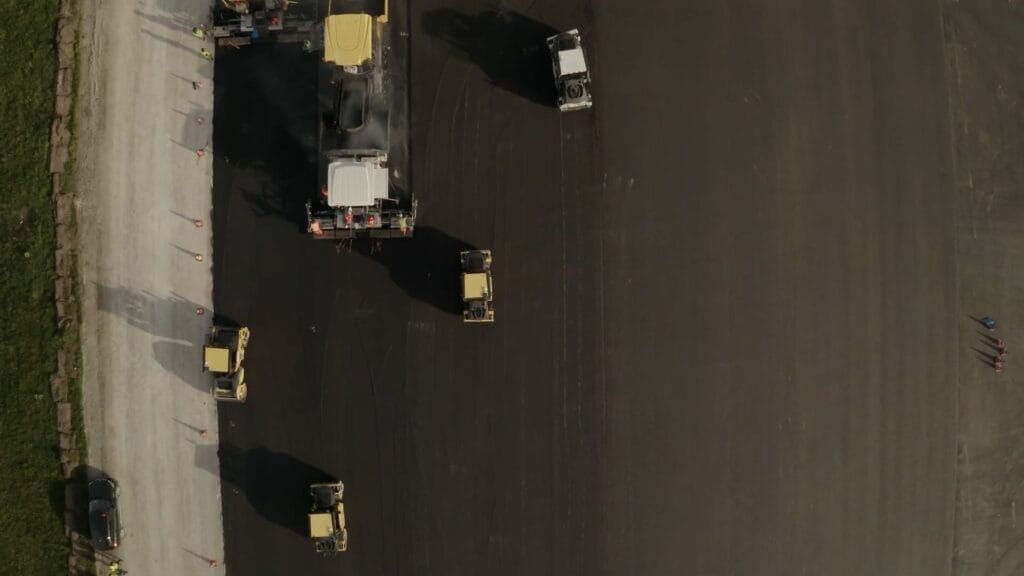

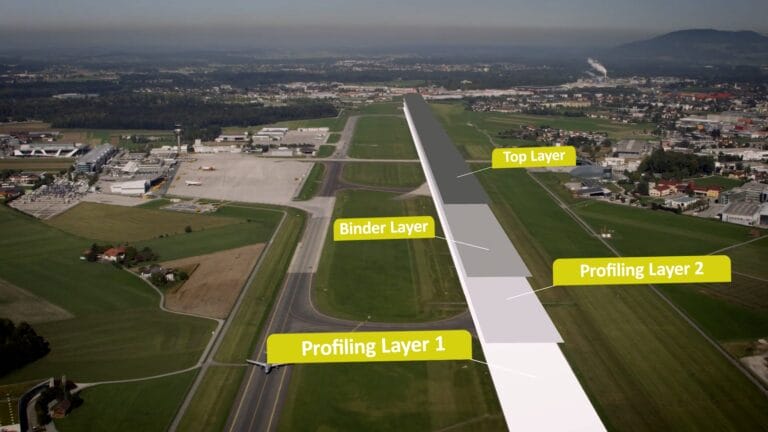

The Salzburg Airport runway overhaul demonstrates the transformative impact of Völkel Intelligent Compaction in modern construction projects. Tasked with ensuring safe take-offs and landings, the project involved removing the old runway and replacing the base layer before the 5-week paving schedule.

Project Details

• Client: Salzburg Airport

• Contractor: PORR, in partnership with STRABAG

• Scope: Comprehensive overhaul of the runway and taxiways, involving 117,000 tonnes of asphalt

Challenges

• Unpredictable weather conditions

• Tight project timeline

• Need for high-quality paving and compaction

Solution

Völkel Intelligent Compaction Measurement was employed to enhance paving quality and efficiency. During the 5-week paving window, 20 rollers worked in unison, sharing individually recorded compaction quality data quality data between each other. This provided operators with a complete picture of all work completed, rather than just their own individual contribution, ensuring optimal compaction and reducing the need for rework.

Benefits

- Uniform Compaction: Pass count targets and mapping ensured operators maintained a uniform rolling pattern

- Improved Density and Productivity: Ensured uniform compaction quality across all surfaces

- Cost and Time Savings: Reduced project duration and maintenance costs

- Enhanced Safety and Reliability: Provided a stable and durable runway for aircraft operations

Conclusion

The Salzburg Airport runway overhaul is a shining example of how intelligent technology and collaborative efforts can lead to exceptional project outcomes. Völkel’s Intelligent Compaction played a crucial role in achieving these results, setting a new standard for future infrastructure projects.