Getting soil compaction right is essential for any construction project. The roller you choose can determine whether your project remains stable and efficient or faces costly issues later. Achieving the right level of soil compaction requires selecting the most suitable equipment from the outset. If you’re wondering which type of roller is most suitable for soil compaction, this guide has it covered. We’ll explore the various roller options, the soil types they work with, and the latest advancements in soil compaction technology. Keep reading to make an informed choice for your next project.

Contents:

Understanding the Different Types of Compaction Rollers

Key Factors to Consider When Choosing a Compaction Roller

Benefits and Applications of Each Roller Type

Determining the Ideal Roller for Your Project

Which Type of Soil Gets Compacted by Vibratory Rollers?

Latest Technological Advancements in Soil Compaction Equipment

Understanding the Different Types of Compaction Rollers

If you’re going to choose the right roller for your next project, you need to understand your equipment options and the type of soil they can compact. Here are the seven main types of compaction rollers and what they do best:

Padfoot Rollers: Fine-grained, cohesive soil requires a high level of pressure to achieve deep compaction. A padfoot roller ticks this box, making it particularly well-suited to clay-heavy sites.

Smooth Drum Rollers: Granular soil or mixed soils that do not clump together behave differently under pressure than cohesive soil. A smooth drum roller creates a smooth finish on the top layer without a kneading / manipulating effect.

Multi-Tyred Rollers: When your team needs a versatile roller that can be used for various soil types, we recommend a multi-tyred roller. An adjustable ballast system fitted to most multi-tyre rollers allows a skilled professional to quickly and easily adjust the “point” pressure to fit the task. This roller class is highly recommended for road construction projects that span various soil types and are also suited to asphalt applications.

Trench Rollers: A trench roller offers a versatile and safe compaction solution. Articulated steering ensures that pressure is uniformly always applied, allowing optimal soil compaction to be achieved quickly and efficiently and well suited to pipework and utilities.

Tandem Rollers: Another popular choice for road/asphalt projects and well suited to most civil applications because of the uniform pressure distribution. The focus here is all on the surface layers so that when you’re working on both asphalt and civil sites you can consistently achieve a smooth finish.

Combination Rollers: If you combine the smooth finish of tandem rollers with the addition of multi tyres to the rear you get a highly versatile piece of compaction equipment. Because there’s never a one-size-fits-all approach to soil compaction, sometimes you need a tool that can adapt to a broader range of compaction needs.

Static 3-Point Rollers: Finally, the 3-point setup and static pressure application without vibration make our 3-point rollers suitable for sensitive areas and proof rolling. Soil compaction is not all about brute force — sometimes what’s needed is a greater level of precision to protect surrounding structures and services. Static 3 Point Rollers are also a roller that can easily detect imperfections.

With the different types of rollers outlined, we can now focus on the key factors that will influence your choice of equipment.

Need a quote for your next hire? Get a Quote.

Key Factors to Consider When Choosing a Compaction Roller

While soil type is always a key consideration, selecting the right roller requires a look at several other important factors. Only then will you be able to take care of soil compaction the right way. Here are four essential elements to consider:

Soil Type and Compaction Requirements: Every soil has unique characteristics. The density and stability that can be achieved will depend on the size of the grains, the degree of cohesiveness, and the level of moisture content.

Operating Weight and Pressure Distribution: A heavier roller that can apply more pressure will compact the soil to a greater degree and a larger depth. Some projects will require more pressure variation than others. It’s always important to remember that the heaviest possible roller is not always the best-suited tool for the job.

Maneuverability and Accessibility: More compact equipment, such as trench rollers, can provide greater precision when working in confined and unsafe spaces. Many construction projects will require a compact solution for key areas that are easy to overlook during initial planning.

Operating Costs and Maintenance: When you have found the right tool for the job, the last thing you want is to discover that it needs continual maintenance. A durable, field-tested design that offers high fuel efficiency and reliability will make all the difference to your project’s timeline.

Now that we’ve covered the key factors, we need to look more closely at which type of roller is most suitable for soil compaction when working with specific material types.

Benefits and Applications of Each Roller Type

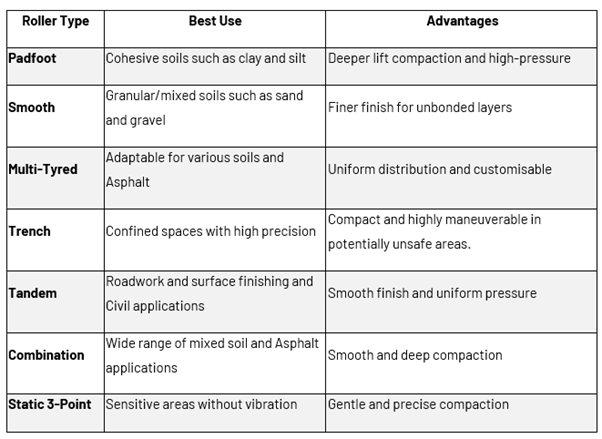

Timely project completion requires an efficient way to select the right tools and equipment. Our quick lookup table will point you in the right direction, allowing you to make strategic decisions quickly:

If the right roller for your project isn’t immediately obvious, stepping back and looking at the bigger picture will help. Multiple factors will always need to be considered, such as the type of material being compacted, the size and scope of the project, and the terrain conditions and moisture content. Consulting with experts or reviewing equipment specifications can also ensure you choose a roller that delivers the best performance and efficiency for your needs.

Determining the Ideal Roller for Your Project

Choosing the right roller for soil compaction can make all the difference to your project’s success. Here are three essential factors to consider when making your decision:

Choosing a Roller Based on Soil Composition: Use the table in the previous section to select a roller based on soil consistency and moisture content. This will ensure optimal compaction across all ground and mix types.

Selecting the Right Size Compactor: You do not need a hammer to crack a nut. If your project only requires compacting a relatively small area, opting for a smaller, lower-cost roller is a smart move. A versatile roller with customisation is best if multiple areas with different soil or Asphalt profiles need to be worked on.

Effects of Using the Wrong Roller: Heavier is not always better when it comes to soil compaction because you may cause unwanted disturbances and in extreme cases you can decompact the site. Likewise, a roller that is too light will also slow down and potentially derail your project.

By focusing on these key factors, you can ensure your projects are completed efficiently and with minimal setbacks. Additionally, it’s important to consider whether the soil type you’re working with would benefit from the use of a vibratory roller, as this can significantly enhance compaction results.

Which Type of Soil Gets Compacted by Vibratory Rollers?

Working with non-cohesive soils requires more than simply applying the maximum pressure. Sand, gravel, and other granular materials may try to push back against the roller if the roller is too heavy or too light and if it is not suited to the material being worked on, resulting in non-uniform compaction regardless of the applied pressure. In most applications, the key is using a vibratory roller that applies pressure while vibrating the individual particles into place. Now that you know which type of soil gets compacted by a vibratory roller, you can make an informed decision.

What Options Do I Have?

Tandem and padfoot rollers both fall into the vibratory roller category, with the final choice determined by the granularity and moisture content of your soil and the size and scope of your project. The Conplant team of roller experts is always available to provide advice so that you can find the optimal solution for your needs. We can even recommend how best to use the latest technological breakthroughs to further improve the speed and efficiency of your next project.

Latest Technological Advancements in Soil Compaction Equipment

As soil compaction technology evolves, it brings new opportunities to complete projects with greater precision and efficiency.

GPS Integration for Precise Compaction Control: Völkel Intelligent Compaction (integrated into Conplant equipment) provides GPS-based control that is best suited to highly accurate compaction over a wide area. Learn more about Völkel Intelligent Compaction and see how it is helping to shape the industry’s future.

Telematics for Fleet Management and Efficiency: Leveraging real-time data will improve equipment utilisation and increase project efficiency. You can also proactively track maintenance and operation schedules to help reduce overall operational costs.

Conplant’s Innovative Solutions: Our skilled team constantly reviews and optimises our approach to delivering optimal soil density. By focusing on efficiency while championing environmental responsibility, we have committed ourselves to making a real difference.

Final Thoughts: The Future of Soil Compaction Technology

Soil compaction is an industry undergoing rapid change and allowing projects to be completed faster than ever before. This is how we’re making a difference:

Eco-Friendly Innovations in Compaction Equipment: Sustainability is vital, and more fuel-efficient rollers that reduce carbon emissions are driving this trend.

Automation and Remote Control Features: Tools like IICAS and remote/unmanned operations are at the heart of Conplant’s mission to make construction smarter.

Conplant’s vision is to continually optimise the soil compaction tools that are available for use in construction projects of all sizes. By providing a comprehensive range of equipment options, we help lay the foundations for smarter construction projects.

Frequently Asked Questions

A padfoot roller uses raised pads to compact cohesive soils like clay and silt efficiently.

Soil compactors are used to uniformly compress soil so that construction projects benefit from increased stability.

Compaction equipment increases the density of soil layers, allowing you to create a stable foundation for a wide range of types of new infrastructure.

A padfoot roller is best when you want to achieve deep compaction on soils such as clay.

Smooth rollers have a flat drum and are typically used when working with granular soils, such as sand and gravel.

Choosing the right type of roller for soil compaction is essential when you want to create a stable, durable foundation. Understanding the specifics of each roller allows you to make the right choice for your next project.