Getting compaction right is crucial for any construction project. Whether you’re working on roads, civil earthworks, or site preparation, selecting the best method can have a significant impact on efficiency and cost and most of all site compaction.

Two of the most widely used methods are Vibratory Roller Compaction and High-Energy Impact Compaction (HEIC). Each compactor has its strengths, and the right choice depends on factors like soil type, project scale, compaction depth and desired outcomes.

Contents:

High-Energy Impact Compaction (HEIC)

Vibratory Roller Compaction vs HEIC: A Practical Comparison

Choosing the Right Compaction Method

Challenges and Limitations of Each Method

Best Practices for Effective Compaction

Vibratory Roller Compaction

Vibratory rollers are the go-to choice for most civil, council and construction projects in Australia. They apply weight, pressure, and rapid vibrations to compact material efficiently, ensuring a solid foundation. The vibratory roller is a staple in compaction due to its effectiveness across various applications.

Key Benefits:

✔ Versatile Across Soil Types – Works well on granular, mixed and semi-cohesive soils.

✔ Fast and Cost-Effective – Covers large areas with fewer passes, reducing project time and fuel costs.

✔ Smooth and Uniform Finish – Ideal for road construction, road maintenance, car parks, and building foundations.

✔ Easy to Operate – Minimal setup, making it a practical choice for a wide range of applications.

Common Applications:

- Road construction, road maintenance and resurfacing using vibratory rollers

- Pavement and car park preparation

- Civil and commercial site development

- Landscaping and ground stabilisation with vibratory rollers

Need to hire a roller for your next project? Contact us today for a quote.

High Energy Impact Compaction

HEIC is a powerful alternative, using impact compactors that delivers a high-energy force into the ground. This method is particularly effective for deep compaction and large-scale projects. While Conplant does not provide HEIC services, we can connect you with our sister company, Landpac Asia-Pacific, if your project requires deep compaction (or Ground Improvement).

Key Benefits:

✔ Deep Compaction – Penetrates multiple soil layers to a higher depth, making it suitable for thick fills.

✔ Efficient for Large-Scale Earthworks – Reduces the need for extensive and costly excavation and backfilling.

✔ Stronger Load-Bearing Capacity – Improves ground stability, essential for heavy infrastructure.

Common Applications:

- Mining and industrial site preparation

- Deep fill stabilisation

- Large-scale earthworks and infrastructure

- Compaction / reclamation of landfill sites

- Aviation site works

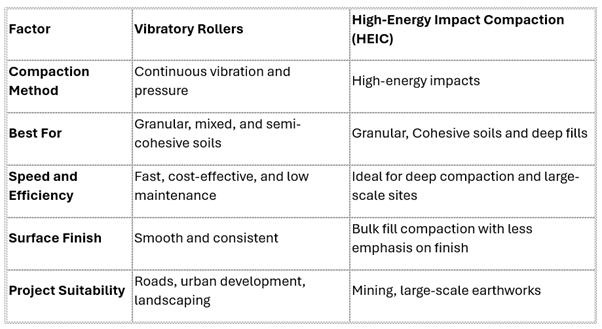

Vibratory Roller Compaction vs HEIC: A Practical Comparison

Choosing the Right Compaction Method

Both methods have their place, and the right choice depends on project requirements:

- Soil Type – Vibratory rollers work best for granular materials, while HEIC works best in granular soils it also is great for cohesive soils.

- Project Scale and Budget – Vibratory rollers are cost-effective for standard projects, while HEIC suits large-scale developments and may provide huge cost savings.

- Surface Requirements – Vibratory rollers provide a smoother finish, essential for roads and pavements.

- Depth of Compaction – HEIC is preferred for deep lift compaction needs in large-scale earthworks.

Challenges and Limitations of Each Method

Every compaction method has its limitations. Understanding these challenges can help in making informed decisions:

✔ Vibratory Rollers – May not be effective for deep lift compaction, particularly in thick cohesive soils.

✔ HEIC – Requires careful application to prevent over-compaction and potential ground vibrations affecting nearby structures.

✔ Project-Specific Suitability – Choosing the wrong method can lead to inefficiencies, damaged compaction surface, increased costs, or inadequate compaction.

Best Practices for Effective Compaction

To maximise efficiency and achieve optimal compaction results, follow these best practices:

✔ Select the Right Equipment – Matching the correct vibratory roller to the soil type ensures better results.

✔ Control Moisture Content – Properly hydrated soil always compacts more efficiently, avoiding excessive or low moisture content is key.

✔ Use the Correct Passes – Over-compaction can be as detrimental as under-compaction; follow recommended rolling patterns / Geotech’s site instructions.

✔ Monitor Soil Density – Regular testing ensures target compaction levels are met before proceeding with the next lift / construction phase.

Environmental and Cost Considerations

Compaction methods impact both the environment and project costs. Here’s what to consider:

Fuel Consumption and Emissions – whilst an impact roller may burn more fuel per hour, they are comparatively a greener option as less equipment is required compared to using vibratory rollers.

Long-Term Cost Efficiency – While HEIC can reduce material excavation, transportation and labour costs in large-scale projects, vibratory rollers offer lower operational costs for routine compaction tasks.

Ground Disturbance – HEIC’s high-energy impacts may cause vibrations that affect nearby structures, whereas vibratory rollers offer a more controlled approach.

Why Partner with Conplant?

With over 60 years of experience in compaction solutions, Conplant provides the right equipment and expert advice to keep your projects moving. If your project requires HEIC, we can put you in touch with Landpac Asia-Pacific, specialists in High-Energy Impact Compaction. For projects requiring vibratory rollers, we have a range of reliable options to suit your needs.

Call us on 1300 166 166 or contact us to discuss your compaction needs today.