What are corrugations in soil & dirt roads (and how to manage them)?

Compaction rollers are used in the construction of dirt roads to compress the soil and create a smooth and stable surface for vehicles to drive on. Corrugations in soil and dirt roads occur when loose material shifts under repeated traffic, forming ridged, wave-like patterns that disrupt surface quality.

In road building, corrugation refers to regular ridges formed by displacement of loose material, creating a wave effect similar to windswept desert sands.

These ridges become more pronounced over time due to the settling of unstable base layers, combined with repeated impact and friction from vehicles. Once the pattern forms, each successive vehicle pass reinforces the ripple, fast-tracking potholes, unevenness and degradation.

What causes road corrugation: The science explained

Road corrugation begins when soil particles move forward under tyre pressure. Rather than flattening out, displaced particles gradually build ridges because vibration, gravity and momentum push loose material into consistent ripple patterns. Without strong lateral support from well-compacted base layers, these corrugations grow rapidly.

How corrugations form (displacement of loose material)

Every vehicle pass shifts soil particles slightly forward or outward. High spots become higher while low spots deepen, forming a repeating pattern. This process accelerates when moisture is low or compaction is uneven, allowing more material to move freely.

Relationship between compaction and corrugation

Well-compacted roads resist particle movement. Poor or uneven compaction allows the top layer to flex under wheel pressure, which encourages corrugation. Achieving consistent density across the full lift depth is the most effective way to prevent corrugations in dirt roads.

Common locations and conditions where road corrugation occurs

Road corrugation is most common on:

• Unsealed rural or remote roads

• Mining haul roads

• Agricultural and forestry access tracks

• Long, straight sections where speeds are higher

• Soil types with low cohesion, such as gravel or sand

Dry, windy conditions and inconsistent moisture content further increase corrugation risk.

The progression of soil corrugation is greatly accelerated where compaction has been insufficient or uneven. Compaction aims to compress soil until it’s tightly packed and resistant to erosion. High-traffic roads with poor compaction often deteriorate fastest, contrary to the belief that traffic might flatten loose material.

Corrugated roads negatively affect comfort, safety, speed and maintenance budgets. A well-prepared, uniformly compacted base layer is the most important factor in preventing corrugations.

Impact of vehicle traffic

Vehicle weight, speed and tyre pressure all contribute to corrugation. Heavy vehicles and stiff suspension systems create stronger vibrations, dislodging loose particles and deepening existing ripples. Even light vehicles contribute once the pattern is established.

Relationship between traffic volume and corrugation

Higher traffic volume typically worsens corrugation rather than flattening it. Every pass reinforces the shape, compacting the ridges and deepening the troughs. Roads with periodic heavy loads often corrugate faster than those with frequent lighter traffic.

When compaction rollers move too quickly, some sections become denser than others. Roller speed directly affects the uniformity of compaction — a key variable in corrugation development.

Effects of roller speed on compaction quality

Speeds above recommended limits reduce the roller’s ability to compact deeper layers, leading to inconsistent density. Optimal roller speeds of 3–5 km/h ensure adequate force is applied evenly, allowing soil layers to bond and stabilise properly.

Corrugations form perpendicular to the direction of travel, producing a bumpy, uncomfortable ride. Rutting, by contrast, forms along the wheel path.

The aim of compaction is to create a flat, durable surface. Short-term “fast rolling” may save time but increases the long-term cost of repairs and grading.

Seasonal and weather impacts on road corrugation development

Hot, dry weather loosens granular soils, allowing corrugations to form more quickly. Wet seasons soften the base, making it more vulnerable to deformation under load. Freeze–thaw cycles in cooler regions can break down cohesive soils, leading to uneven settlement.

Soil composition factors that contribute to corrugation

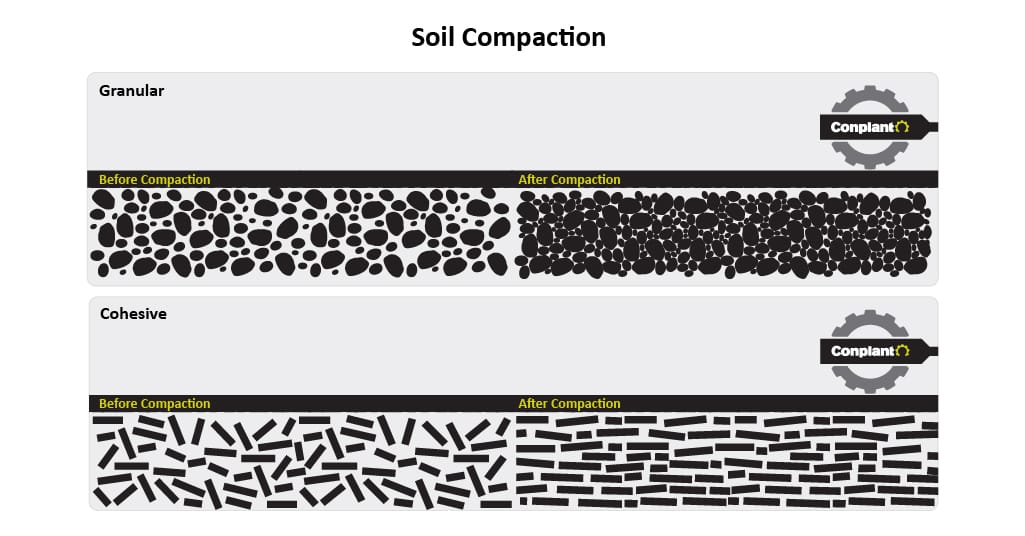

Granular soils (sand, gravel) corrugate easily because they lack cohesion. Clay-rich soils hold their shape better but only when compacted and moisture-conditioned correctly. The more uniform the particle size and moisture content, the more resistant the surface is to corrugation.

Project timelines and budgets often dictate a speedy approach, but there’s a high risk that this will prove more costly in the long-term. So, what are some of the dangers posed by poor soil compaction?

Effects of corrugations in dirt roads

Corrugations cause noticeable vehicle vibrations and discomfort — but the impacts extend far beyond ride quality.

Corrugated roads reduce tyre contact with the surface, making steering less predictable and braking less effective. They also place strain on vehicle suspensions, frames and transported goods due to constant jolting.

Economic impact of road corrugation on communities and businesses

Businesses reliant on transport face increased repair costs, slower travel times and greater fuel consumption. Councils and road authorities absorb higher grading and maintenance costs. For remote communities, corrugations can disrupt access to healthcare, supplies and emergency services.

Environmental effects of corrugated roads

Corrugations force vehicles to travel at lower gears and higher revs, increasing emissions and dust levels. Dust reduces visibility and coats surrounding vegetation, affecting plant health and soil quality. Poorly compacted surfaces also erode more easily, harming nearby waterways.

How to avoid corrugations on dirt roads

Achieving a smooth, durable finish relies heavily on roller speed, soil moisture, lift thickness and compaction technique.

For most soil types, 3–5 km/h is the recommended roller speed. Slower travel speeds compact thicker lifts more effectively.

Read more in our simple guide to compaction

Best practices for road corrugation prevention in different environments

- Arid regions: Adjust moisture levels before compaction

- Wet climates: Improve drainage to prevent soft subgrades

- Mining/industrial roads: Use heavier rollers and enforce speed limits

- Agricultural and forestry routes: Increase grading frequency during busy seasons

Tailored approaches reduce both corrugation development and long-term maintenance costs.

Cost-benefit analysis of proper corrugation prevention vs repairs

The upfront cost of correct compaction and preparation is far lower than the ongoing cost of frequent grading, rework and vehicle repairs. Roads built to standard have significantly longer service life and reduced upkeep. Prevention always delivers stronger economic outcomes.

The more tightly bound a surface is, the more resistant it becomes to future corrugation. Thorough preparation is always preferable — but remediation is possible when corrugations appear.

Remediation of existing corrugations

Where corrugation has occurred, maintenance personnel can drag, grade or re-compact the road surface to restore smoothness.

Dragging or grading techniques

Light corrugations can often be smoothed using a grader or drag blade to break the ridges and redistribute material. This is a common maintenance method for rural dirt roads.

Re-grading and re-compacting

Moderate to severe corrugations require the surface to be cut deeper, reshaped and compacted in thin lifts to restore uniform density. Moisture conditioning may also be needed before compaction.

Non-vibrating passes with rollers

Finishing with static or non-vibratory roller passes tightens the surface without disturbing the newly reworked layer, improving longevity.

Step-by-step guide to fixing corrugated roads

- Scarify or loosen the corrugated layer

- Add moisture if required

- Cut high points and fill low areas

- Compact in controlled lift thicknesses

- Finish with sealing passes

- Inspect density and shape before allowing traffic

Frequency recommendations for maintenance schedules

Most unsealed roads require grading every 8–12 weeks. High-traffic industrial roads may require weekly or fortnightly maintenance. Climate and soil type influence the ideal maintenance schedule.

Which compaction roller is best suited to my project?

The nature and scope of each job will determine which size and type of compaction roller is best suited for your project. In some cases, a combination of various rollers may be required. There are a number of rollers capable of road building and maintenance applications, including:

- Smooth drum roller 6-8t / 11-14t / 14-16t / 16-18t Ideal for compacting a wide range of materials including gravel, sand and other granular or non-cohesive mixed soils. Well suited to industrial sites, driveways, road construction and repair.

- Padfoot roller 6-9t / 11-14t / 14-16t Mid-to-large sized padfoot rollers are highly effective on building sites and for main road construction. They can handle high-volume, heavy-duty compaction work on most types of soil and clay masses.

- Tandem roller 1-2t / 2-3t / 4-5t / 7-9t / 9-14t A vibrating drum makes it ideal for road base and smooth asphalt finishes on jobs where it’s important to keep up with incoming materials – for example, following an asphalt paver on major road projects, highways, large parking areas or driveways.

- Multi-tyred roller 3-4t / 5-12t / 9-10t (vibrating) / 12-18t / 18–24t Suited to compacting sub grades, road base and asphalt finishes including preparation and application of asphalt, spray seals and some stabilisation projects. Ideal for road maintenance and construction, such as large civil projects or local highways.

- Combination roller 3-5t / 7-8t / 9–10t Great for compacting thin layers and soft asphalt compounds, making them ideal for road maintenance, large civil projects and local highways.

- Trench roller These multi-purpose compactors are generally used for trench compaction. Trench rollers are used by electricians, plumbers and builders to securely bury cables and pipes and for the compaction of roads and car parks, among other applications.

Need a hand getting your next project on the road? Give us a call on 1300 166 166 or get an online quote now.

Check out Australia’s most comprehensive roller hire range and get the job done.